Regenerative Thermal Oxidiser

-

-

Product Description:

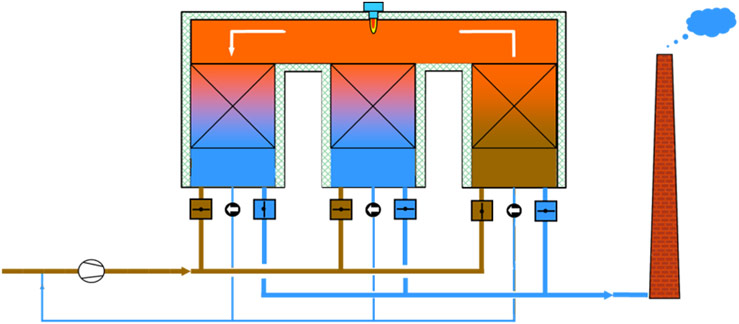

For the purification of industrial exhaust gases, ceramic heat storage materials are used in the plant to efficiently process the exhaust gases generated and collected in the various stages of production, realizing high economic energy savings. Even under very high exhaust gas flow conditions, the plant operates efficiently in a system-optimized manner. At the same time, with the use of thermal storage ceramic heat storage, the system is able to realize self-supporting heat operation of the plant under suitable concentration solvent conditions.

Downloads

For the purification of industrial exhaust gases containing high concentrations of organic pollutants, the INTEGRA and FLEXA series of units are characterized by a high level of utilization of the heat in the system. In combination with a downstream heat recovery system, the complete unit has low operating costs and requires only a small amount of external fuel heating.

The heat storage ceramics are used to heat the inlet gas, supplemented by a burner heated to a set temperature for oxidative decomposition, and then most of the heat is absorbed by the heat storage ceramics when it is discharged. The airflow direction is switched regularly by the airflow switching valve to circulate the heat absorption and exothermic process of the heat storage ceramics.

Distinctiveness

Units with 2, 3 or more beds

Industrial areas where solvents are used

■ 2-bed ■ 3-bed ■ multi-bed ■ With buffer system ■ Rotary valve type

Plug-and-play

|

Smart 系列RTO 选配表 |

||

|

规格 |

Smart 系列 |

|

|

基本数据 |

风量范围(Nm³/H) |

1000~30000 |

|

排放浓度(mg/Nm³) |

< 20 |

|

|

热交换效率 |

> 95% |

|

|

选配设备 |

缓冲罐 |

○ |

|

热旁通 |

○ |

|

|

Chimneys |

○ |

|

|

废溶剂焚烧系统 |

○ |

|

|

LEL检测装置 |

○ |

|

|

FID在线浓度检测系统 |

○ |

|

|

…… |

○ |

|

|

余热回收方式 |

热水 |

○ |

|

热风 |

○ |

|

|

导热油 |

○ |

|

|

激冷 |

○ |

|

|

发电 |

○ |

|

|

备注:1.以上所列为代表性规格型号,具体规格详见技术合同 2.“○”代表可选项 |

||